2017 Aluminum Alloy Plate

Aluminium is an essential material that makes working easy in construction and marine industries, its alloys, on the other hand, are also crucial. One of the most famous and used aluminium alloys in the market is ALUMINIUM 2017 alloys. In general, all the aluminium 2017 alloys that got molded into sheets and plates are heat treatable wrought material with intermediate strength capacity. It is much stronger and ductile compared to other grades in the aluminium alloy series. Corrosion resistance is completely fair whereas resistance weldability and arc weldability is satisfactory.

Aluminium Grade: 2017

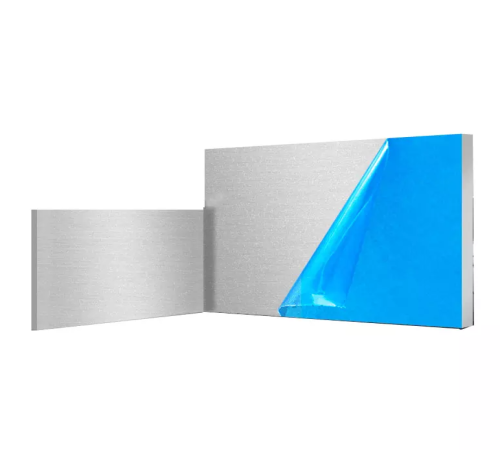

Width: 500-2500mm

Thickness: 0.5-35mm

Length: 500-10000mm

Temper: O, T3, T4, F,etc.

Certificate: DNV/ABS/Lioyds/BV

Packing: blank waterproof paper, kraft, wooden case or pallet (fumigation report for the wooden packing material)

Features: very good elongation, anti-corrosion performance

Overview of 2017 Aluminum Alloy Plate

The aluminium 2017 plates have low density and appropriate melting point both in metric as well as in imperial. What makes it so essential in industries? It is yielding strength, shear strength, elongation (annealed), tensile strength (annealed), and elastic modulus. Similar to density and melting point, you can get in metric and imperial units too. Other property that makes it an ideal product is thermal expansion and thermal conductivity. The aluminium alloys exhibit other designated forms also. Know how machinability formability and welding have an impact on it.

Features of 2017 Aluminum Alloy Plate

Formability and machinability- In T4 temper, aluminium 2017 acquire the first-rate machinability. Oil lubricant usage is highly recommended when machining operations. In annealed conditions, it shows excellent formability.

Welding- it is said that welding reduces the corrosion resistance, that’s why it should be ignored whenever possible. However, heat treatment can be performed in accordance so as to regain corrosion resistance. Other welding techniques such as resistance welding, inert gas welding can be used.

Annealing- the aluminium 2017 is easy in solution at a temperature ranging 504 degree Celsius or 940 degrees Fahrenheit. Using water quenching, 3, as well as 4 phase, can be followed easily. At room temperature, age hardening can be performed easily in order to produce T4 temper. Annealing gets performed at a temperature around 413 degrees Celsius or 775 degrees Fahrenheit.

Applications of 2017 Aluminum Alloy Plate

-Aerospace components

-Rivets

-General structural components

-Transportation

-Fasteners

-Screw machine products

-Gauges

-Pulleys

-Needles for knitting

Manufacturer of 2017 Aluminum Plate

Staral Alloy is a professional aluminum supplier, providing users with different types of aluminum products. The price of aluminium is not only low, but also has high corrosion resistance. We strictly control the production process of each product to ensure high quality.

Chemical composition of 2017 Aluminum Alloy Plate

The following table shows the chemical composition of aluminium / aluminum 2017 alloy.

Element | Content (%) |

Aluminum, Al | 91.5 - 95.5 |

Copper, Cu | 3.5 - 4.5 |

Iron, Fe | 0.7 max |

Manganese, Mn | 0.4 - 1 |

Magnesium, Mg | 0.4 - 0.8 |

Silicon, Si | 0.2 - 0.8 |

Zinc, Zn | 0.25 max |

Titanium, Ti | 0.15 max |

Chromium, Cr | 0.1 max |

Remainder (each) | 0.05 max |

Remainder (total) | 0.15 max |

Mechanical Specifications of 2017 Aluminum Alloy Plate

Properties | Metric | Imperial |

Tensile strength (annealed) | 179 MPa | 26000 psi |

Yield strength (annealed) | 69 MPa | 10000 psi |

Elongation (annealed) | 22% | 22% |

Elastic modulus | 72 GPa | 10500 ksi |

Shear strength (annealed) | 124 MPa | 18000 psi |

Send an Inquiry

Your email address will not published. Required fieled are marked.