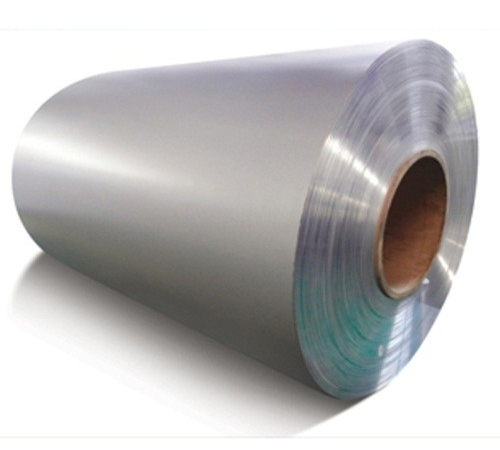

3003 Aluminum Alloy Coil

3003 aluminium alloy is an alloy in the wrought aluminium-manganese family (3000 or 3xxx series). It can be cold worked (but not, unlike some other types of aluminium alloys, heat-treated) to produce tempers with a higher strength but a lower ductility. Like most other aluminium-manganese alloys, 3003 is a general-purpose alloy with moderate strength, good workability, and good corrosion resistance. It is commonly rolled and extruded, but typically not forged. As a wrought alloy, it is not used in casting. It is also commonly used in sheet metal applications such as gutters, downspouts, roofing, and siding.

Aluminium Grade: 3003

Width: 500~2600mm

Thickness: 0.2~12mm

Temper: O, H24, H34, H16, H26, H36, H18, H28, H38, H112, F,etc.

Certificate: DNV/ABS/Lioyds/BV

Packing: blank waterproof paper, kraft, wooden case or pallet (fumigation report for the wooden packing material)

Features: very good elongation, anti-corrosion performance

Overview of 3003 aluminium alloy coil

Aluminium alloy 3003. In most cases, this is probably the best alloy for bending. You get average strength, very good cold workability and high elongation. It also offers one of the biggest differences between yield and tensile strength.

Features of 3003 aluminium alloy coil

Good weldability, formability and corrosion resistance.

Applications of 3003 aluminium alloy coil

It is commonly rolled and extruded, but typically not forged. As a wrought alloy, it is not used in casting. It is also commonly used in sheet metal applications such as HVAC, hinges, condensers, radiators, evaporators, heat shields, gutters, downspouts, and roofing and siding.

Manufacturer of 3003 aluminium alloy coil

Staral Alloy is a professional aluminum supplier, providing users with different types of aluminum products. The price of aluminium is not only low, but also has high corrosion resistance. We strictly control the production process of each product to ensure high quality.

Chemical Composition for 3003 aluminium alloy coil

Element | Percentage(%) | ||

Aluminum | (Al) | Remainder | |

Silicon | (Si) | 0.6 max | |

lron | (Fe) | 0.7 max | |

Copper | (Cu) | 0.05~0.20 | |

Manganese | (Mn) | 1.0~1.5 | |

Magnesium | (Mg) | ||

Chromium | (Cr) | ||

Zinc | (Zn) | 0.1 max | |

Titanium | (Ti) | ||

Remainder | Each | 0.05 max | |

Remainder | Total | 0.15 max |

Mechanical Specifications of 3003 aluminium alloy coil

MECHANICAL PROPERTIES | |||||

O | H14 | H24 | H18 | ||

UItimate Strength Rm/MPa | 95~135 | 145~185 | 145~185 | 2190 | |

Yield Strength Rp0.2/MPa | 235 | 2125 | 2125 | 2170 | |

Elongation Min.% | 20.2~0.5mm | 215% | ≥ 2% | 24% | 21% |

Bend Radius (90°) | 2.0.2~0.5mm | 0t | 0.5t | 0.5t |

1.5t |

Send an Inquiry

Your email address will not published. Required fieled are marked.