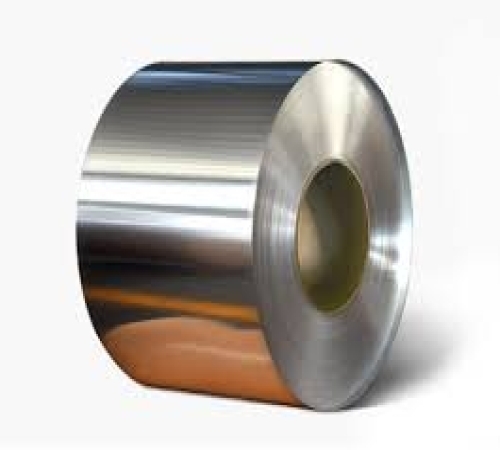

1050 Aluminum Alloy Coil

1050 aluminium alloy is an aluminium-based alloy in the "commercially pure" wrought family (1000 or 1xxx series). As a wrought alloy, it is not used in castings. Instead, it is usually formed by extrusion or rolling.

Aluminium Grade:1050

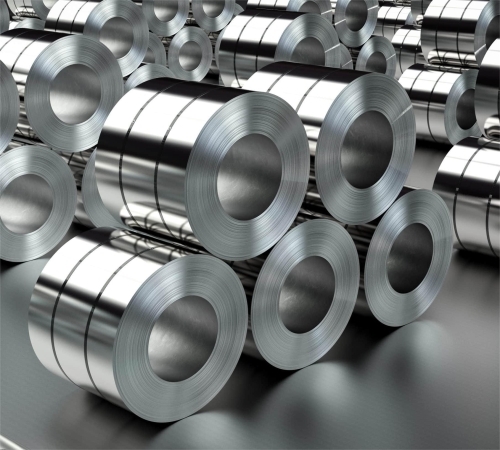

Width: 500~2600mm

Thickness: 0.2~12mm

Length: Coil

Temper: H18, H112, H26.

Certificate: ISO9001, CNAS, OHSAS18001

Packing: blank waterproof paper, kraft, wooden case or pallet (fumigation report for the wooden packing material)

Features: very good elongation, anti-corrosion performance

Overview of 1050 Aluminum Alloy Coil

1050 Aluminum alloy is an commercially pure wrought aluminum based alloy with 99.5% aluminum and 0.4% Fe. This alloy is usually used in cold rolling or extrusion. This family of alloy has high electrical conductivity, corrosion resistance, and workability. But has low mechanical strength in comparison to other aluminum alloys. The 1050 alloy is a well rounded product that is suited for chemical and electrical applications.

Features of 1050 Aluminum Alloy Coil

1050 aluminum coil has high ductility and a highly reflective finish. Besides, 1050 aluminum coil is non-heat treatment series is produced in extruded sections. It has excellent cold workability, braze-ability, and solder-ability, and it is strengthened by cold working.

Applications of 1050 Aluminum Alloy Coil

It is commonly used in the electrical and chemical industries, on account of having high electrical conductivity, corrosion resistance, and workability. 1050 alloy is also sometimes used for the manufacture of heat sinks, since it has a higher thermal conductivity than other alloys. It has low mechanical strength compared to more significantly alloyed metals. It can be strengthened by cold working, but not by heat treatment.

Manufacturer of 1050 Aluminum Alloy Coil

Staral Alloy is a professional aluminum supplier, providing users with different types of aluminum products. The price of aluminium is not only low, but also has high corrosion resistance. We strictly control the production process of each product to ensure high quality.

Chemical Composition of The 1050 Aluminium Coil

Elements | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al |

Content | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | – | 0.07 | 0.05 | 0.15 | Remain |

Physical Properties of Aluminium Alloy 1050

Property | Value |

Density | 2.71 kg/m3 |

Melting Point | 650°C |

Modulus of Elasticity | 71 GPa |

Electrical Resistivity | 0.282 x 10-6 Ω.m |

Thermal Conductivity | 222 W/m.K |

Thermal Expansion | 24 x 10-6/K |

Send an Inquiry

Your email address will not published. Required fieled are marked.