1100 Aluminum Circle/discs

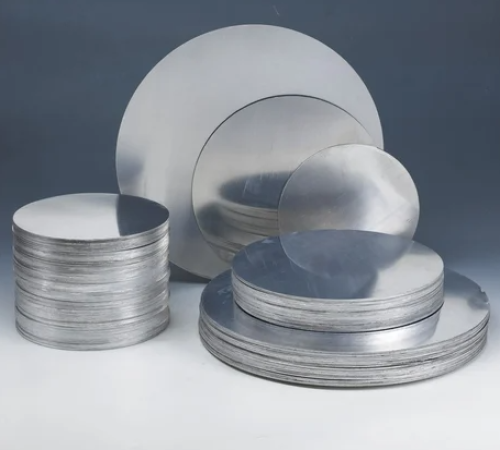

Aluminum discs or circles in various sizes and thicknesses are commonly used to manufacture products, as well as more creative uses. Products manufactured with aluminum circles include capacitors, medical tubes and kitchen wear, as well as beverage cans. The circles are often drawn with presses into various sizes.

1100 Aluminum circle/disc/disk

Alloy: 1100

Temper: O, H12, H14

Thickness range: 0.36mm ~ 5mm (Or customized according to customer requirements)

Diameter range: 120mm - 1000mm (Or customized according to customer requirements)

Process: Hot rolled (DC) or Cold rolled (CC)

Standard: GB/T 24001-2016, GB/T 19001-2016, ASTM, JIS, EN

Certificates: ISO9001,SGS, ROHS,DNV,TUV,ISO14001,ABS,CCS,CE,Kosher

Overview of 1100 Aluminum circle/discs

Alloy 1100 is highly resistant to chemical attack and weathering. It is a relatively soft alloy that is very formable and is used extensively in thin gauge and foil products. It has good welding characteristics and it is also used as a filler alloy for welding purposes.

Features of 1100 Aluminum circle/discs

Wide range of selection on circles' size including customized shape and size.

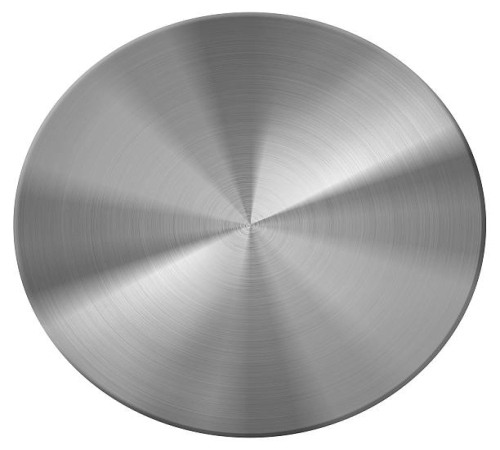

Excellent Surface Quality for lighting reflectors.

Excellent deep drawing and spinning quality.

We provide heavy gauge circles with thicknesses up to 6mm thick which is ideal for cookware.

Anodizing Quality and Deep Drawing Quality which is suitable for cookware as well.

Well-Protected Packing

Applications of 1100 Aluminum circle/discs

1.Ordinary cookware: post-process: sanding, sandblasting, extrusion pot lid; aluminum pot;

2.Lamp accessories: lampshade, etc. for downlights, laminate lights and street lights

3.Indication signs and building materials: traffic signs, curtain walls, ceilings

Supplier of Aluminum circle/disc

Staral alloy is a professional aluminum manufacturer providing different size and alloy types of aluminum products. Create reliable quality, let customer satisfaction is our pursuit. After the customer receives the goods, our after-sales personnel will follow up in time to provide perfect after-sales service.

Aluminium 1100 Circles Chemical Composition

Grade | The Element Max(%) | |||||||||

1100(min) | Fe | Si | Mg | Mn | Cu | Zn | Ti | Cr | Others | Al |

0.35 | 0.25 | 0.01 | 0.01 | 0.05 | 0.01 | 0.020 | Trace | 0.05 (each) | 99.6% | |

1100(max) | 0.50 | 0.35 | 0.03 | 0.05 | 0.20 | 0.05 | 0.030 | Trace | 0.15 | remainder |

Mechanical Properties of Aluminum 1100 Circles

Alloy | Temper | UTS(Mpa) | % Elongation | |||

Min | Max | 0.5 mm -0.8 mm | 0.81 mm - 1.30 mm | 1.30 mm - above | ||

1100 | O | 75 | 110 | 20 | 25 | 29 |

H12 | 95 | 130 | 5 | 6 | 7 | |

H14 | 110 | 145 | 3 | 4 | 5 | |

H16 | 130 | 165 | 2 | 3 | 4 | |

H18 | 150 | --- | 2 | 2 | 3 | |

Send an Inquiry

Your email address will not published. Required fieled are marked.