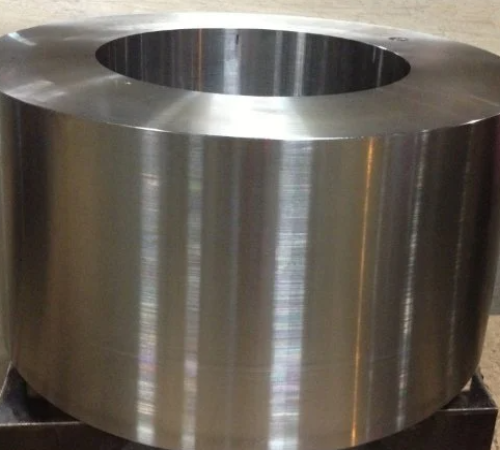

1xxx~8xxx series aluminum alloy forges

Aluminum forging alloys are aluminum with small additions of other elements that enhance the final properties of the component. Aluminum forgings are normally produced in high volume. Because of aluminum’s low density relative to steel, it is not surprising that aluminum alloys are used extensively in industries where component weight is important. Consequently, aluminum forging alloys are used primarily in automotive and aerospace applications.

Aluminium Grade: 1xxx~8xxx

Width: Customized

Thickness: Customized

Length: Customized

Temper: O,T6, H112,T4,T351,H18, H19, H22, H24, H32, H111, H321, etc.

Certificate: DNV/ABS/Lioyds/BV

Packing: blank waterproof paper, kraft, wooden case or pallet (fumigation report for the wooden packing material)

Features: very good elongation, anti-corrosion performance

Overview of Aluminum Forges

Aluminum or aluminum alloy forged articles are called aluminum forgings.

Features of Aluminum Forges

1. Low density

2. The surface is smooth and clean, with good surface treatment performance, beautiful and durable.

3. High specific strength, high specific rigidity, high specific elastic modulus, and high fatigue strength. It is applicable to key stressed parts with high lightweight requirements, and its comprehensive performance is far superior to other materials.

4. The internal structure is fine, uniform and free of defects, and its reliability is much higher than that of aluminum alloy castings and die castings, and also higher than that of other metal castings.

5. The aluminum alloy has good plasticity and can be processed into high-precision forgings with complex shapes. The machining allowance of parts is small, which is only about 20% of the aluminum alloy round bar plate.

6. Aluminum alloy forgings have good corrosion resistance, thermal conductivity and non-magnetic properties, which are incomparable to steel forgings.

Applications of Aluminum Forges

1. Aluminum profiles are used in automatic assembly lines and material transfer equipment manufacturers. Industrial aluminum profiles can be customized to support automatic assembly lines, such as conveyor line support, stacker and shuttle rail, etc.

2. Aluminum profiles are used in production equipment workbench of electronic industry. The workbenches and operation consoles in the electronic industry are all assembled from aluminum profiles and aluminum alloy plates or other materials.

3. Aluminum profiles are used in automatic production lines of packaging industry. The automatic production line in the packaging industry is generally a belt conveyor line workbench customized by aluminum profiles, which is transported while packaging.

4. Aluminum profiles are used in the worktable of industrial detection system. The workbenches of the industrial detection system are the operation workbenches and detection workbenches. These workbenches are made of aluminum alloy profiles, which are not only anti-corrosion but also very easy to clean.

5. Aluminum profiles shall be used for assembly of parts in automobile industry. The parts assembly industry needs not only workbenches but also industrial fences and aluminum profiles for mold opening. Many auto parts are also customized from aluminum profiles.

6. Aluminum profiles are used in chemical, pharmaceutical, medical and food industries. The application of aluminum profiles in the chemical, pharmaceutical, medical and food industry is reflected in the application of workbenches and dust-free purification workshops. The performance of aluminum alloy with high anti-corrosion hardness and high cleanliness meets the needs of this industry.

Supplier of Aluminum Forging

Staral alloy is a professional aluminum manufacturer providing different size and alloy types of aluminum products. Create reliable quality, let customer satisfaction is our pursuit. After the customer receives the goods, our after-sales personnel will follow up in time to provide perfect after-sales service.

Aluminum Rod | ||

Standard | ASTM B221M, GB/T 3191, JIS H4040,etc. | |

Material | 5052,5652, 5154, 5254, 5454, 5083, 2014,2014A,2214,2017,2017A,2117 | |

5086, 5056,5456, 2024, 2014, 6061, 6063,6082, etc. | ||

Diameter | 6-800mm | |

Length | 2m,3m,5.8m,6m,or as required | |

Surface | Mill finish,polished,anodizing,brushing,sand blasting,powder coating,etc | |

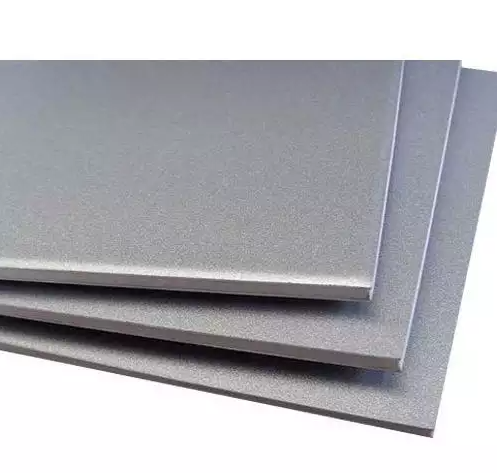

Aluminum Sheet | ||

Thickness | 0.15-200mm or as requeted | |

Width | 1000mm, 1219mm, 1250mm, 1500mm,or as customer's request | |

Length | 1000mm,1500mm,2000mm,or as as customer's request | |

Material | 1050,1060,1100,3003,3004,3105,5052,5005,5083,6061,6063,7075,ect | |

Temper | O, H12, H14, H18, H22, H24, H32, H34, H36,T3,T5,T6,ect | |

Surface | painting, anti-rust or as customer's request | |

Aluminum Pipe | ||

Specifcation for round pipe | OD | 15nm-160nm |

WT | 1-40mm | |

Length | 1-12m | |

Specification for square pipe | SIZE | 7X7mmm- 150X150 nlm |

WT | 1-40mm | |

Length | 1-12m | |

Application | 1) Kitchenware, food and chemical products processing and storage devices; | |

2) Aircraft fuel tanks, oil pipe, rivets, wire; | ||

3) Cans cover, car body panels, steering plates, stiffeners, brackets and other components; | ||

4) Manufacturing trucks, tower building, ship, train, furniture, machinery parts, precision machining with the tubes, rods, | ||

Aluminum Grade | ||

Alloy Series | Typical Alloy | |

1000 Series | 1050 1060 1070 1100 | Pure aluminum |

2000 Series | 2024(2A12), LY12, LY11, 2A11, 2A14(LD10), 2017, 2A17 | Aluminum copper alloy |

3000 Series | 3A21, 3003, 3103, 3004, 3005, 3105 | Aluminum manganese alloy |

4000 Series | 4A03, 4A11, 4A13, 4A17, 4004, 4032, 4043, 4043A, 4047, 4047A | Aluminum silicon alloy |

5000 Series | 5052, 5083, 5754, 5005, 5086,5182 | Aluminum magnesium alloy |

6000 Series | 6063, 6061, 6060, 6351, 6070, 6181, 6082, 6A02 | Aluminum magnesium silicon alloy |

7000 Series | 7075, 7A04, 7A09, 7A52, 7A05 | Aluminum magnesium silicon alloy |

8000 Series | 8006 8011 8079 | Aluminum foil alloy |

Send an Inquiry

Your email address will not published. Required fieled are marked.